|

| My Chainsaw |

As a fan who's purchased three copies of

The Evil Dead, five copies of

Evil Dead 2, and three copies of

Army of Darkness (thanks to Anchor Bay's multiple double dip releases) I'm ecstatic about the resurgence of this franchises popularity. For years I perused sites such as

Deadites.net and

EvilDeadNews.com looking for any nugget of information about the potential of a new movie. I purchased a PS1 just to play

Hail to the King, I mainlined games such as

A Fistful of Boomstick and

Regeneration. Hell, I even re-edited all three movies (with game audio) into a very well received

four hour edit that was covered by

Yahoo Movies. Now that

Ash vs Evil Dead is out, one would assume that my thirst for the franchise should be quenched. Well, I suppose it has not.

For the last few years I've been collecting screengrabs, lists of materials, and scouring the internet for any information I could find about how to build my own screen accurate chainsaw. About two weeks ago, I pulled the trigger. Building it from start to finish took me about five, eight hour days and about $200 in parts. In this article I'll take you from start to finish through the process of building your own version of one of the most iconic movie props of all time. Be sure to read through the entire article and get a feel for the process before spending the money and time as this is not the easiest of ordeals. Below is a list of materials and tools needed to complete this project.

Tools Required:

Grinder (with cutting wheel, grinding wheel, and wire wheel), Dremmel (with cutting & sanding wheels), drill, handsaw, screwdrivers, adjustable wrench, trigger clamps, normal clamp, vice grips, a vice, toothbrush, & safety glasses.

Materials:

Homelite XL Chainsaw,

3D printed grille, 20 inch chainsaw blade and chain, 3 1/2 inch T-Bolt Clamp, 3 1/2 inch metal door kickplate, a 1 inch wide aluminum flat bar, a 1 inch diameter oak rod, two 90 degree metal brackets, three 2 inch metal brackets, Bondo, sandpaper, JB Weld, wood filler, two 1/4 inch carriage bolts one inch in length w/nuts, two 1/4 inch bolts 1/2 inch in length w/nuts, two 1/4 inch Phillips head bolts 2 inch long w/nuts, five 1/4 inch bolts 1 inch in length w/nuts, one wood screw.

Paint:

Rust-Oleum Satin Paprika Paint+Primer, flat black primer, red acrylic, silver model acrylic, and ebony stain.

The Body:

|

| Chainsaw Before |

The base object in this build is obviously the chainsaw itself, which is a Homelite XL Chainsaw*. I suggest searching on eBay. Since you only truly need the materials, feel free to purchase a dirty, non-working model. I got mine for $53 after shipping.

*If you have industrial tools, time, and wish to make a version of this that is metal instead of the screen accurate plastic version, you could purchase the Homelite Super XL 2 Chainsaw. Yes, it results in a much sturdier product, but from all accounts it is a nightmare to work on, and is so heavy you will not want to wear it.

The first thing you want to do is take it apart and clean it up as these have a tendency to be caked in oil and grease both inside and out. Remove the sawblade with an adjustable wrench, and take out all external screws holding it together. Be sure to place all of your nuts, bolts, and screws into a magnetic catch tray as this will assure you don't lose them when reconstructing it.

|

| The Wife Hated Me for This |

After, you'll notice that the engine is now floating inside the body. Take off the exhaust (one long screw) and set it aside for later. Remove the spark plug and throw it away. This will free the engine to be released. Take it aside and place it in the bucket as it is likely disgusting with years of built-up grease. Now it's time for the least fun step: cleaning. You could use some type of industrial degreaser, but many of these tend to harm the plastic body, so I heavily advise against using them, Get yourself a high-quality dish soap and prepare to wash it a dozen times with the toothbrush. If necessary, take a flat head screwdriver and scrape the grime off. Repeat this process until clean.

|

| Cut Guide |

Now it’s time to actually get to work. To the right of this are the lines of which you want to use to cut along, but if you pay attention to the natural seam of the body, it's quite self-explanatory. Use the Dremmel cutting discs to do this. Be quite careful as you do and wear safety glasses as this will produce liquid plastic as you cut (I got hit in the eye doing this, don't be like me). Cut slowly and don't rush as you have one chance at this. Once you're through, take the sandpaper (or a sanding Dremmel bit) and knock down the rough edges that you've created. Up next is attaching the kickplate, which will act as the top of the chainsaw.

Top of Chainsaw

This is one of the harder aspects of creating the chainsaw. You could just attach a metal plate and call it a day and that would indeed be a screen accurate version of the first chainsaw seen in

Evil Dead 2 (as he assembles it) but I don't like the look. Furthermore, that's not the chainsaw seen in the rest of

Evil Dead 2,

Army of Darkness, or

Ash vs Evil Dead, so it wasn't an option for me. Also, I wanted to construct as much of this as possible, but if you'd like, you can purchase this piece pre-built for $75 from

Evil Dead Workshed, but that's not the way I wanted to go.

|

| Kickplate Position |

The kickplate ($11 at hardware store) will have two pre-drilled holes which are perfectly placed to attach it to the front of the chainsaw. If the lip of the front of the chainsaw doesn't let it sit perfectly, just grind it down with the Dremmel. Place the plate where you intend to mount it, mark your holes and drill them. Attach them with the two 1/2 inch length bolts w/nuts you've purchased. Once mounted, this is where your eyes need to take over in lieu of directions. You'll want to bend this metal by hand to resemble the arc of the original, you can see in my picture the arc I settled on. When you're content with the design, bend the end to meet the natural bend of the saw where your hand will eventually be. Cut the metal there and you can use a clamp to keep it in place for now. Make yourself a little piece of JB Weld (mixing a piece of the epoxy substance) and place it between the saw and the metal where your clamp rests, this will help temporarily hold it in place.

Now that we have the plate in place, we need to take the on/off switch we previously removed from the saw and drill a hole from it on top of the saw where you feel it should be. Throughout the course of the movies and the episodes, many chainsaws are used and the placement on this switch varies (sometimes shot to shot). Watch some of the franchise and decide where you want to place your switch, drill a hole for it and mount it because once we do the next step, it would be a pain to add it afterwards.

|

| Pour Walls |

Filling in the top is where growing up working in car bodyshops came in handy for me. It was there where I first learned to work with Bondo (fiberglass filler). You will need to create walls to pour against, and bondo will stick to nearly every surface, but, it will NOT stick to wax paper. Cut yourself two pieces of cardboard that roughly match the walls of what you want to pour and trim them to match the natural contour of the chainsaw top. Next, wrap them in wax paper and tape it to itself, these will act as the walls you pour against. You can hold the walls in place as I have in the picture with several clamps.

|

| While Filling |

Mix yourself some Bondo. If you've never worked with the substance before, I suggest you make a small amount of it and play with it. See how long it takes to dry, when it becomes too solid to use. Get comfortable with it before attempting this. Hold the saw upside down, and pour the Bondo into the makeshift mold. Some will come out the sides and the top will not look pretty. All of this is fine and we will deal with it shortly. If you're worried about making too much or it starts to harden, don't worry, throw away what you've made, make more and pour over top as it will attach to the existing Bondo as it hardens. Note: The drying chemical process will become extremely hot as it's a lot of Bondo on metal, do not burn yourself and have an area prepared to be able to sit the object safely down.

Once throughout dried, remove the false walls. It won't be pretty, don't worry, it's not supposed to be. Sand down the sides with 80 grit sandpaper until the sides are smooth. Some pores and holes will remain, simply make yourself a small amount of Bondo and use a plastic scraper to fill it in. Let it dry, sand it back down and repeat this process until you are happy with the look. Use this time to also fill in any remaining screwholes on the plate. Congrats, you've made the bulk of your saw.

Optional Step

I chose to primer my chainsaw, sand it back down and primer a few more times. This allows you to fill in tiny holes, knicks, and issues with the body and make it look a little prettier. Simply use the flat black primer, spray, sand with 220 paper, and repeat until happy.

Oil and Gas Chambers

This part is easy, simply clean them and cut the tops off of the chambers. Afterwards epoxy them back into place and you're ready to go. Just be sure to tape them off before you're ready to spray paint them.

The Wood Handle:

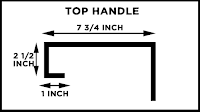

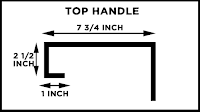

|

| Top Handle |

This is where the vice comes in handy, however it can be done by using the hard edge of a table. This is pretty self-explanatory, but I will go into as much detail as possible. From studying miscellaneous images of the screen used saws, it seems that most of them stand about two and a half inches above the saw itself and the top of it is 7 3/4 inch in length. Again, if you're feeling lazy, this finished part is available on

Evil Dead Workshed for $30.

|

| Top Handle Diagram |

The 1 inch aluminum bar cost me $7 at a hardware store. First is the bend that attaches itself to the top of the chainsaw, which is one inch. So measure one inch from the beginning of the aluminum plate and bend it at a 90 degree angle. The next bend will be the actual handle, so two and a half inches up, bend again at 90 degrees. From that bend, measure over 7 3/4 inchs, and bend again at 90 degrees. Place this on top of the chainsaw where you will mount it and see where it naturally falls to the edge of the chainsaw where you place your hand into. Mark the metal at the lip of it, and that's where you cut it off.

Once you're happy with the shape of the metal, grind off the edge of the handle where it mounts to the chainsaw as on screen it's not a square, it's an oval edge. Drill a 1/4in hole into the center of the mount. You now have the metal section of the handle.

|

| Sanding Handle |

For the wood (the rod was $3), the length of it should be 7 1/4, but in case you haven't nailed it 100%, simply measure the handle you've made and make adjustments if need be. Cut the wood accordingly. Next, you'll need to split the wood in half. Be sure to measure and mark very precisely as the smoother this is, the better it will look in the final product. The cutting of this can be accomplished by either placing the wood in a vice or cutting it by hand, or by using the cutting disc of the Dremmel. Once cut in half, you'll want to either cut off the corners at a 45 degree angle, or this can be accomplished by sanding.

Once finished, sand with 80 grit sandpaper until smooth and then final sand with 220 paper afterwards. When you're happy with the handle, mark in on inch from the sides of each piece and drill a 1/4in hole. Place them on the metal handle and mark the whole marks with a sharpie on the metal where you will mount it. Afterwards, drill 1/4in holes into the top of the metal as well.

|

| Carriage Bolt Diagram |

To mount the wood to the metal you will use the one inch carriage bolts you've bought. This requires drilling half inch holes halfway into the top of the wood. Note, these holes DO NOT go the whole way through, they simply allow you to "sink" the head and nut of the carriage bolt into the wood. Do this process incredibly slowly and allow the drill to eat into the wood, DO NOT force it. If you force it, you could possibly make the drill catch too much hold and it will crack the wood in half. I went through two of these making mine. Next, align the wood to metal, place the bolts in and tighten. Congrats, you have the handle*.

*If you're not happy with the smoothness of the metal to wood contact, or if you have chipped the wood, simply apply wood-filler and sand back down until smooth, the wood-filler will accept stain and look fine.

Stain the handle with ebony stain by rubbing on a small amount over the entirety of the wood (and filler) and wiping it off. Repeat this process until the desired color is obtained.

The Metal Side Handle

The longer piece of the handle needs cut. What is handy about this is it is incredibly easy to measure, simply make both overhanging sections the same size. In essence, cut off the longer end to be 1/2 inch longer than the end that is inserted into the chainsaw. Now, you'll want to fill in the cut off piece to be screen accurate. Simply mix some Bondo (or JB Weld), and stick it down the neck of the metal stem to create a cork about an inch in. Allow that to dry and repeat the process, but this time form an overhanging ball on the top of it. All you need to do is sand it down afterwards and paint it with black primer.

The Motor/Exhaust Mount

|

| Motor |

This is arguably the most difficult section of the process and requires a lot of patience. First, use the brake cleaner on the engine and get most of the grime off. Next, you're going to want to slowly, carefully, and safely cut off 3/4 of the engine. What you will leave is where the blade attaches to the motor, and where the exhaust attaches as well. To accomplish this, use the grinder with both the grinding and cutting wheels. Cut accurately according to the picture I have provided and you will be fine, but be sure to not remove the hole for the bolt that mounts the motor into the body.

The center spindle which spins the motor will have to be cut which will cause the blade mount to fall off. Simply cut the rod to fit and glue it to the motor in the correct place with JB Weld. When finished, paint with black primer. Use this opportunity to primer the exhaust pieces as well.

Make Room

Since you're almost ready to paint, we need to make sure we're done sanding/cutting the body and have room for your hand. Temporarily bolt the engine in, and the body back together. Does your hand fit in? Probably not. In order to make it, we're going to take the sanding attachment for the Dremmel and slowly eat away at the exposed hole until you can easily insert your hand. Simply work in circles around the opening of the hole (while not grinding away any of the screw mounts) until you can comfortably insert your hand.

Paint:

|

| Painted Body |

Take the body back apart and spray the pieces separately. If you've never spray painted, practice on another object first. Once you feel comfortable, we'll be using the Rust-Oleum Satin Paprika Paint+Primer spray paint, which is the closest to screen accurate pre-made spray paint that exists. If you want to get 100% accurate paint, take the handle you cut off to the local automotive paint store and have them computer match it. The problem is that will require you to have both a paint-gun and an air compressor.

The best advice I can offer when painting is to get a complete coat on the entirety of both pieces. This is best accomplished by screwing the removed bolts from the chainsaw body, reattaching them while leaving half of the bolt exposed, and hanging them in suspension by the bolt. This will allow you to get total coverage on the pieces.

The Saw Blade

Once again, throughout the franchise many blades were used, but the one that resembles most all of them is the 20 inch chainsaw blade from Oregon (Got mine for $32 on Ebay). The only thing really to do here is to remove the paint. For this, I personally grinded it off, then polished it with the wire-wheel attachment. However, any way you get the paint off is fine. Other options include airline paint remover (nasty stuff, use heavy duty gloves), sanding, or perhaps you've bought a blade that doesn't have any paint. Additionally, use the grinder on each razor tooth of the chain in order to dull it to touch.

Optional step

I personally don't care for the blade to look shiny. We'll get to aging the saw towards the end of the article, but if you want to age the blade, the time is now. I tried several means of this, but I landed success after heavily priming the blade in black, and then using the wire-wheel attachment on it afterwards to make it look used.

Install Internal Handle

|

| Internal Handle |

First, bolt the motor back into place through the bottom of the body and put it in its permanent place. Next up is installing the internal handle which you will hold on to while wearing the chainsaw. To do so, simply measure inside the saw from the bottom to the Bondo top and cut a section of the oak rod to fit. Mark on the bottom of the body where that will go and run a woodscrew through the body and into the bottom of the wood. To secure it, press together a good chunk of JB Weld and form it around the top of the rod and the bottom of the body, essentially creating a base around the top and bottom of the internal handle. Allow this to dry for about 20 minutes.

Install Aluminum Handle

Next up, place the top handle where you wish to mount it and mark the hole in the bottom of the aluminum handle with where the hole will be drilled into the top of the body. Since you'll be drilling through both metal and Bondo we need to take sever precautions. We don't want the bondo and the steel on the top to separate due to the force, so use the trigger clamps to hold the piece solid while we drill. To accomplish this, you'll want to drill a series of guideholes, working up to the 1/4 inch hole you need in the end. Then, install the two inch Phillips head bolt through the top and loosely secure it with the nut on bottom.

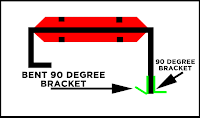

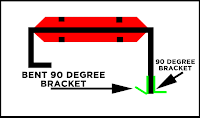

|

| Mount Diagram |

For the loose side of the handle, you'll be using the two 90 degree brackets, one to attach the handle to the body, the other to attach both to the arm-cuff coming up soon. The bracket that attaches to the body will need to be bent in order to fit, so squeeze it with the vice grips until it's the appropriate size. Once it fits, use a marker to mark where you'll drill the hole on the body as well as where you'll drill into the aluminum handle. Once marked, take the handle back off the body.

Once removed, drill into the body the same way as you drilled the previous hole, using a series of guideholes and using clamps to assure the bondo doesn't separate from the metal. After, drill a 1/4in hole into the back of the handle so that you can place a bolt adjoining all threel. Install the bent bracket as well as the 90 degree bracket onto the handle, then reattach the entire piece to the body (you may need to mess with the order of placing in the bolts due to space). Tighten the handle onto the top of the body, if excess bolt remains inside, simply use a grinder or the Dremmel to remove it.

Add the Grille and Pull Start

|

| From Thingiverse |

First, you can either purchase the 3D grille for

$20 online, from Thingiverse or download the blueprints for free and print it yourself. The grill is cake to paint, just order it in black and paint the outside with either the silver model paint, or a chrome Sharpee marker. Mix a small amount of glue epoxy and glue it on, the 3D model provided is the exact perfect size. Allow to dry for 15-25 minutes.

|

| Pull Start |

While that is drying, take the remaining oak rod and cut a three inch section from it. Drill a 1/4in hole through it, and then, much as you did the handle, drill a 1/2in hole through half of it, this is so once the cord is fed through it, you can tie and it will rest in it. Again, do this slowly as you risk the pull start cracking and chipping. When finished, stain just as you did the handle. Feed the cord through the wood, tie one end, and pull tight. Feed it through the hole in the body and glue it to the inside.

Once both are dry, bolt the entire body and black metal handle back together using the original bolts. We're in the homestretch now!

The Armcuff

|

| Armcuff Closeup |

Take your 2 inch metal brackets and grind the corners off, one of each of these will be attached to the existing screw hole of the body of the chainsaw, so make sure you take an adequate amount off. This is most easily done using the grinder while either holding the piece with the vice-grips or in the vice. Next up is a tough one, drilling the holes into the T-bolt clamp.

Your clamp should have the adjustable end placed directly upwards to the right of the back of the saw (see picture). First we will drill the hole for the 90 degree bracket, so place it in place and mark the clamp with a marker where the hole should go. It is important to remember while drilling that this is hardened metal and is not easy to drill. Therefore, hold the clamp in the vice, and drill a series of guide holes. I suggest again drilling guide-holes, starting with a 3/32 bit, a 1/8th bit, 3/16 bit and finally the 1/4in bit. Once finished, loosely bold the cuff to the 90 degree bracket with a 1/4in bolt one inch in length.

Now, unscrew the two bolts in the back of the body of the saw and install the two inch brackets. Use your vice-grips to bend them into roughly the place they line up on the T-Bolt Clamp and mark the hole with a marker. Take the cuff off, and using the previously described means, drill the holes necessary for install and bolt them using the other 1 inch long bolts.

Optional Step:

Many people make two more brackets and install them at the bottom of the chainsaw to the cuff, however I couldn't find sign of them actually existing in the movies so I did not. The three bolts in mine are far more than enough for it to be bolted securely, but to each their own.

Final Touches

|

| Non-aged Chainsaw |

Bolt the chainsaw blade back on and reattach your chain. Additionally, reattach your exhaust to the motor. If you need to touch up any red paint, spray it into jar and use a brush. Also, take your silver model paint and apply over any bolts that you've painted red.

CONGRATULATIONS YOU'RE DONE! KINDA!

Well, mostly. Yes, you're finished, but it doesn't look that cool if it's clean. Feel free to keep it that way if you wish, but wouldn't it look way cooler with some blood and grime?

Aging

|

| My Chainsaw |

Aging is a process that's half delicate work, and half pure slop. Arguably, the best ever done

video on the subject was done by Adam Savage from Mythbusters and should be considered required viewing on the subject. The process I used was taking black enamel and dry brushing (YouTube tutorials on the subject) the corners where the saw would throw dirt, and miscellaneously around the body. I also took the silver model paint and "weathered" the corners. This is accomplished by using a small brush and aggressively using small strokes on the edges to simulate chipped paint. Repeat this process until you are happy.

Blood

|

| After Blood Effect |

I researched and tested many various forms of blood before I came upon what I used. Most of what people suggested resulted in sticky, dark substances that I did not want near my hard work. What I ended up using is an epoxy. Take your clear drying, two part epoxy and cut the handle so that they can be pushed separately. Empty one tube into a dish. Next, add red enamel paint until you reach your desired color. Then add the second tube of the epoxy and stir quickly.

This will set fast, but the thing to keep in mind is that the sooner you apply it, the more liquidy it will be. So the longer you let it dry before applying, the more coagulated it will appear. Place your chainsaw on newspaper, dip a dry stiff bristled brush in the red substance, and then fling it at the chainsaw from a few feet away. Concentrate on the blade, but don't shy away from the saw itself. Attack both sides of the chainsaw equally and if you do it in stages, the blood will build on itself in layers. This should dry to touch in 25 minutes (longer than normal due to the additional enamel).

In Conclusion

|

| Final Product |

Congratulations, you're the proud owner of a screen accurate Evil Dead chainsaw! Yes, you could purchase one online for $350, but doesn't it make your fanboy pride swell that you've accomplished the task all by yourself? There are several variations you can place on this as the chainsaw is ever evolving in the franchise (for instance, the wood handle now has electric tape on it in the show). Customize it, make it your own. If a part doesn't fit? Hack away on it and make it, just do it slowly. There are not rules in this process and this article is only a guide to the way I constructed mine. Have fun, make it your own, and long live Ashy Slashy!

I root for The Cincinnati

Reds, but I’m not a “sports guy” by any means. I grew up in Middletown, Ohio

and my uncle Bill would quite often take me out the ballpark to catch games

whenever he was in town. It was there that I developed my love of baseball despite not regularly following the sport. Rather than keeping up

with the latest developments in the game, I spent my youth sitting in front of my

Grandmother’s TV and recorded old replays of The Big Red Machine on VHS tapes.

I root for The Cincinnati

Reds, but I’m not a “sports guy” by any means. I grew up in Middletown, Ohio

and my uncle Bill would quite often take me out the ballpark to catch games

whenever he was in town. It was there that I developed my love of baseball despite not regularly following the sport. Rather than keeping up

with the latest developments in the game, I spent my youth sitting in front of my

Grandmother’s TV and recorded old replays of The Big Red Machine on VHS tapes. My ancestor Edd Roush played for the team from 1916 to 1926,

he even coached the team during the 1931 season. Though I’d like to say he’s

famous for his amazing fielding, he’s a Roush and we’re a rather anti-authoritarian

family. Legend goes that on June 8th, 1920 there was a disagreement

going on between the managers and the umpires. The argument went on for so long

in fact, that Edd decided to take a nap in center field. Either he was

incredibly comfortable or incredibly obstinate, because the Umpires could not

awake him when play resumed and he was kicked out for delaying the game.

My ancestor Edd Roush played for the team from 1916 to 1926,

he even coached the team during the 1931 season. Though I’d like to say he’s

famous for his amazing fielding, he’s a Roush and we’re a rather anti-authoritarian

family. Legend goes that on June 8th, 1920 there was a disagreement

going on between the managers and the umpires. The argument went on for so long

in fact, that Edd decided to take a nap in center field. Either he was

incredibly comfortable or incredibly obstinate, because the Umpires could not

awake him when play resumed and he was kicked out for delaying the game. For 24 years, Waite Hoyt was the voice of The Cincinnati

Reds. Beyond being a legendary storyteller, the man was best known for calling

games in the past tense. Rather than stating “here’s the pitch” he would say “there

was the pitch”. He felt this was more accurate, quite correctly explaining, "…as

I speak to you, what happened a moment ago is gone." Though he was a

recovered alcoholic, he had a strong loyalty to one of The Reds main sponsors,

Burger Beer. The man had such a fixed moral compass that after the team

replaced Burger Beer with Wiedemann, he chose to instead retire rather than

promote a new beer as he thought his credibility may be tainted. In 2007, he,

Marty Brennaman and Joe Nuxhall were honored by The Reds with replica

microphones hung under the radio booth at The Great American Ball Park.

For 24 years, Waite Hoyt was the voice of The Cincinnati

Reds. Beyond being a legendary storyteller, the man was best known for calling

games in the past tense. Rather than stating “here’s the pitch” he would say “there

was the pitch”. He felt this was more accurate, quite correctly explaining, "…as

I speak to you, what happened a moment ago is gone." Though he was a

recovered alcoholic, he had a strong loyalty to one of The Reds main sponsors,

Burger Beer. The man had such a fixed moral compass that after the team

replaced Burger Beer with Wiedemann, he chose to instead retire rather than

promote a new beer as he thought his credibility may be tainted. In 2007, he,

Marty Brennaman and Joe Nuxhall were honored by The Reds with replica

microphones hung under the radio booth at The Great American Ball Park. As you can tell, my Grandfather didn’t keep this vinyl in

immaculate shape, but it is entirely listenable audio and is likely the best

this record will sound without a professional machine cleaning. I dusted off

any loose debree, soaked this vinyl with cleaner, scrubbed it clean, and used a

wet-dry vacuum to remove the grit and dirt from years of abuse. I ripped this

on my Pro-Ject USB turntable into Audacity, capturing at 16bit and normalizing

it after. Next I took a sample of the surface noise and removed it from the

entire project. Afterwards, I ran a de-clicker and de-popper to remove more

noise. I then exported this into 16bit FLAC files and 320mbps MP3’s.

As you can tell, my Grandfather didn’t keep this vinyl in

immaculate shape, but it is entirely listenable audio and is likely the best

this record will sound without a professional machine cleaning. I dusted off

any loose debree, soaked this vinyl with cleaner, scrubbed it clean, and used a

wet-dry vacuum to remove the grit and dirt from years of abuse. I ripped this

on my Pro-Ject USB turntable into Audacity, capturing at 16bit and normalizing

it after. Next I took a sample of the surface noise and removed it from the

entire project. Afterwards, I ran a de-clicker and de-popper to remove more

noise. I then exported this into 16bit FLAC files and 320mbps MP3’s.